Flexible Intermediate Bulk Containers (FIBCs) have sparked a monumental revolution in the realm of bulk material storage, transportation, and handling. These ingeniously designed containers have completely transformed the way industries deal with large quantities of goods, streamlining processes, enhancing efficiency, and ensuring safety. Within the expansive universe of FIBCs, one category stands out for its paramount importance in safeguarding non-flammable and non-combustible materials—Type A bags.

In this comprehensive blog, we embark on an exciting journey to unravel the multifaceted world of Type A FIBC bags, delving into their diverse types and unrivalled applications. With an emphasis on their remarkable features and unparalleled benefits, we aim to provide a holistic exploration of how these exceptional bags cater to the precise requirements of industries across various sectors.

Type A FIBCs are constructed using non-conductive polypropylene fabric without any special anti-static properties. The fabric used in Type A FIBCs is a standard material that does not possess inherent electrical conductivity. It is designed to be non-conductive, meaning it does not facilitate the flow of electrical charges. This fabric is commonly used for various types of FIBCs and is known for its durability, strength, and resistance to moisture.

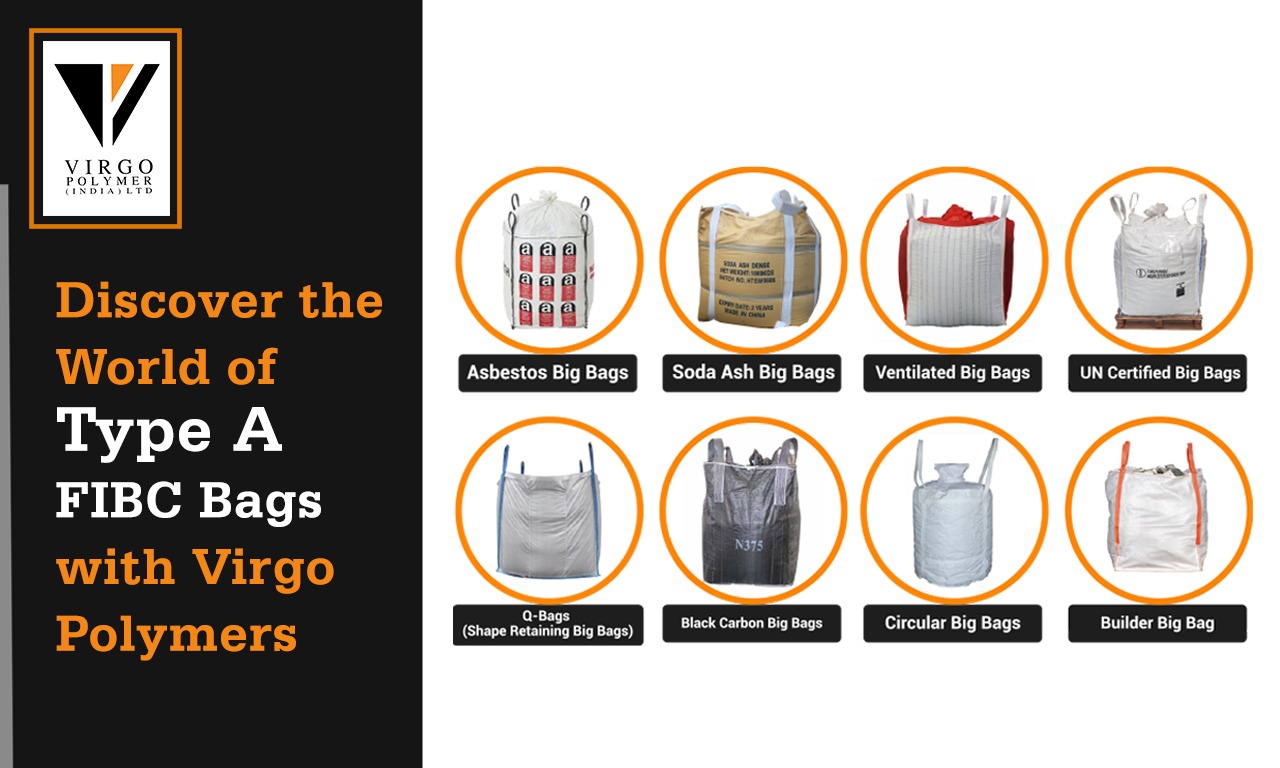

Let's delve into a multitude of Type A FIBCs while comprehending their versatile applications and varied usage.

Asbestos Big Bags

Purpose: The primary purpose of Asbestos Big Bags is the safe handling and disposal of asbestos-containing materials. Asbestos poses severe health risks when its fibers are released into the air, making proper containment crucial. Features:

Specialized Construction: Asbestos FIBCs are constructed with materials and design features that prevent the release of asbestos fibers, ensuring maximum safety during handling and disposal.

Regulatory Compliance: These bags comply with regulations and standards for the containment and transportation of hazardous asbestos waste, providing a reliable solution for asbestos-related operations.

Applications: Asbestos Big Bags are commonly used by contractors, demolition teams, and waste management companies involved in the removal and disposal of asbestos-containing materials. They are an essential tool in maintaining a safe and controlled environment while handling this hazardous substance.

Black Carbon Big Bags

Purpose: Black Carbon FIBCs are specifically designed to protect light-sensitive materials from UV radiation and sunlight exposure. Features:

UV-Stabilized Materials: These bags are manufactured using UV-stabilized materials with excellent light-blocking properties, preventing the degradation or alteration of light-sensitive contents.

Versatile Applications: Black Carbon FIBCs find applications across various industries such as agriculture, pharmaceuticals, and the chemical industry, where light-sensitive materials need to be shielded from harmful UV rays.

Applications: Black Carbon Big Bags are ideal for storing and transporting items like agricultural seeds, pharmaceutical ingredients, dyes, and other light-sensitive products that require protection from UV radiation.

Circular Big Bags

Description: Circular FIBCs are tubular bags without side seams, offering enhanced strength, stability, and load-bearing capacity. Features:

Seamless Design: The absence of side seams improves the bag's structural integrity, enabling it to withstand heavy loads without the risk of seam failure.

Applications: Circular Big Bags are suitable for various industries that require reliable bulk material storage and transportation, including construction, mining, and recycling. It is used in industries where bulk materials like aggregates, sand, gravel, and construction debris need to be stored, transported, or handled safely and efficiently.

Ventilated Big Bags

Purpose: Ventilated FIBCs are designed to provide efficient airflow for products that require ventilation, such as agricultural produce or firewood.

Enhanced Air Circulation: These bags feature ventilated panels or mesh material construction, ensuring improved airflow and preventing moisture buildup or spoilage.

Preserving Product Quality: The proper ventilation offered by these bags helps maintain the freshness and quality of ventilated products during storage and transportation.

Applications: Ventilated Big Bags are commonly used in the agriculture industry for storing and transporting products like potatoes, onions, firewood, or other items that require proper air circulation to prevent spoilage or condensation.

UN Certified Big Bags

Purpose: The UN Certified Big Bags are specifically designed to comply with international regulations governing the safe transportation of hazardous materials.

Compliance: UN Certified Big Bags adhere to international regulations, such as the United Nations Recommendations on the Transport of Dangerous Goods. Compliance ensures that these bags are suitable for transporting hazardous materials without compromising safety.

Product Quality: UN Certified Big Bags undergo comprehensive testing, including drop tests, stacking tests, and leakage tests, to ensure their ability to withstand the demands of transportation and protect the contents from leakage or contamination.

Applications: UN Certified Big Bags are crucial in industries that handle and transport hazardous materials. They are commonly used for powders, granules, or liquids that may pose risks during handling and transit.

Builder Bags

Purpose: Builder Bags, also known as construction FIBCs, are versatile bags designed specifically for construction sites and the handling of bulk construction materials.

Description: The bags are constructed with durable materials that can endure rough handling, abrasion, and exposure to the elements commonly encountered in construction sites.

Product Quality: Builder Bags are crafted to withstand the challenging conditions of construction environments. Their robust construction ensures durability and reliability, allowing them to withstand heavy loads and demanding handling without compromising the integrity of the contents.

Applications: Builder Bags find extensive application in the construction industry, serving as an essential tool for storing and transporting various construction materials. These bags are used for storing and moving items like sand, gravel, stones, construction debris, and other bulk materials. They streamline construction operations by providing a reliable and convenient solution for material storage and transportation on-site.

Type A FIBC bags offer specialized solutions for the safe handling, storage, and transportation of non-flammable and non-combustible materials. Each type of bag serves specific purposes and applications, ensuring compliance with regulations, providing product integrity, and enhancing efficiency in various industries. By understanding the features and applications of these Type A FIBC bags, industries can make informed decisions to optimize safety and streamline their bulk material handling processes.

Would You like to know more?

At Virgo Polymers, we take pride in being the forefront manufacturer of Type A Flexible Intermediate Bulk Containers (FIBCs), offering a comprehensive range of high-quality bags designed to meet diverse industry needs. With our commitment to excellence, we have established ourselves as a trusted partner, providing top-notch solutions for safe storage, transportation, and handling of non-flammable and non-combustible materials.

Call us to know more @ +91 90030 48815 or email us at info@virgopolymer.com